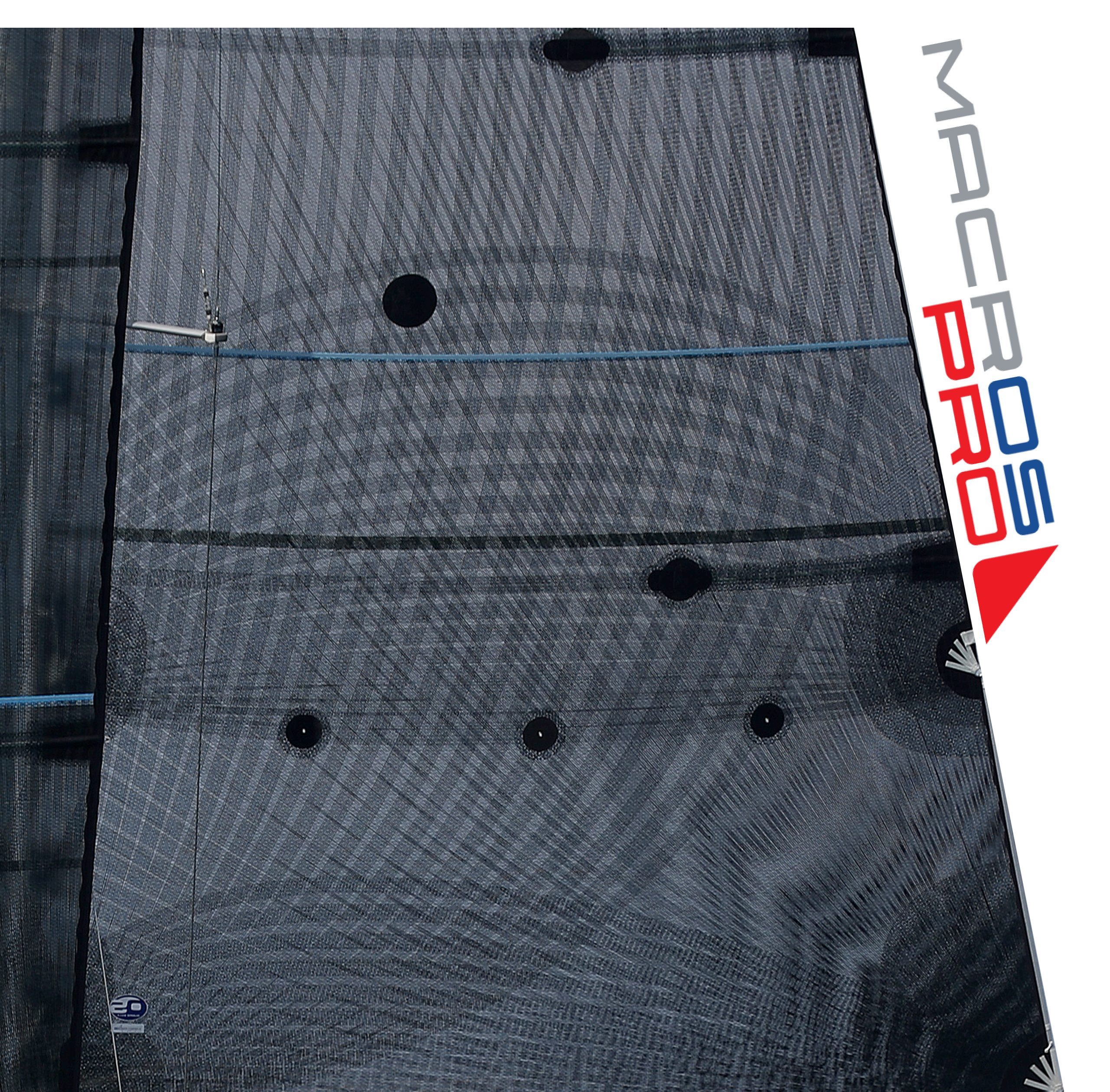

MACROS® MEMBRANES

MACROS® is a membrane obtained with a technologically advanced and constantly evolving lamination process; thanks to the constant work of our technicians and the collaboration with the University, the Sincrotrone and the Area di Ricerca of Trieste that test the materials we are using and those we are developing for the future.

It is the high-performance line developed by Olimpic Sails team after 20 years of experience in the field of membrane sails, totally produced in our in-house Lamination-Lab.

This type of membrane exploits without compromise all the technological quality available in this field, with the use of carbon fiber in combination with the DYNEEMA for inshore and offshore competition sails. This guarantees greater stability and perfect shape retention over time.

This technology relies on a 3D design calculation software that allows designers to define in detail the loads in all parts of the sail. The fiber’s layout is therefore customized, according to the specifications of each single sail, granting the best structure with a considerable reduction of weight.

The sails are made with an external finish in materials that favor lightness and shape stability, elements necessary to obtain high performance in regattas.

Fibers, layers and details of the sails are customizable and artfully crafted based on the peculiar characteristics of the boat and the specific owner's needs. Total control during all steps of construction, from design to finishing, allows us to guarantee a product of the highest quality made in Italy.

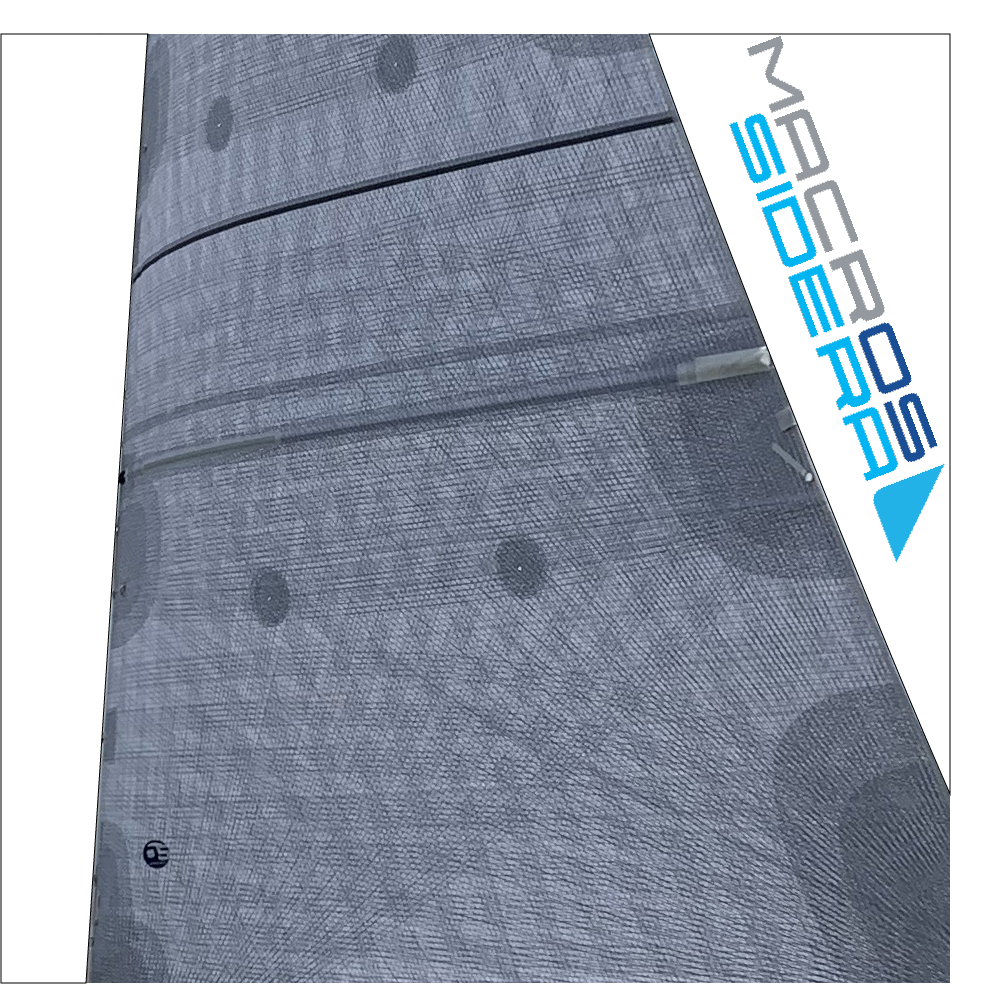

It is the high-endurance line, developed by our team after 20 years of experience in the field of membrane sails, totally produced in our in-house Lamination-Lab. This technology shares components and operating procedures with the Macros Pro®.

After hundreds of membrane sails made with this technology, dedicated to Maxi yachts and the most demanding racing boats, our goal is to bring many traditional cruisers closer to the “world” of modern membranes.

The basic idea is that even when cruising, fast and light sails make sailing more efficient, fun and safe; also technologically advanced materials are more suitable to respond to unexpected and heavy loads.

To achieve this goal, a durable product, easy to use and maintain, has been developed, with the ambition to satisfy any sailor, not only the most demanding.

This technology relies on a 3D design calculation software that allows designers to define in detail the loads in all parts of the sail. The fiber’s layout is therefore customized, according to the specifications of each single sail, granting the best structure with a considerable reduction of weight.

The sails are made with different axternal layer which protects the fibers from wear and exposure to UV.

All membranes are protected by an anti-mildew treatment to ensure a longer duration.

The 100% use of Dyneema fibers ensures exceptional shape retention over time. Your sails will keep the same shape chosen by the designer after years of use.

Compared to traditional materials, the weight of these membranes is up to 30% less, so ensuring better sailing performances and easier handling once lowered.

Fibers, layers and details of the sails are customizable and artfully crafted based on the peculiar characteristics of the boat and the specific owner's needs. Total control during all steps of construction, from design to finishing, allows us to guarantee a product of the highest quality made in Italy.

100% QUALITY MADE IN ITALY

The entire production process takes place exclusively inside our laboratory; this allows us to supervise every single phase from A to Z in order to be sure of the high quality of the product placed on the market.

Testing all the materials used in our processes at University Research Centers and constant monitoring of the entire production chain to ensure compliance with the procedural parameters, from the reception of raw materials to the finishing details, allow us to offer the customer a quality standard very high.

5 YEARS WARRANTY

The continuous Research and Development on materials and resistance tests carried out with the University and the Synchrotron of Trieste and many years of experience and positive results of the use of our membrane sails in all the seas of the world, allows us to offer our customers a 5-year delamination warranty (*).

(*) for yachts up to 80'

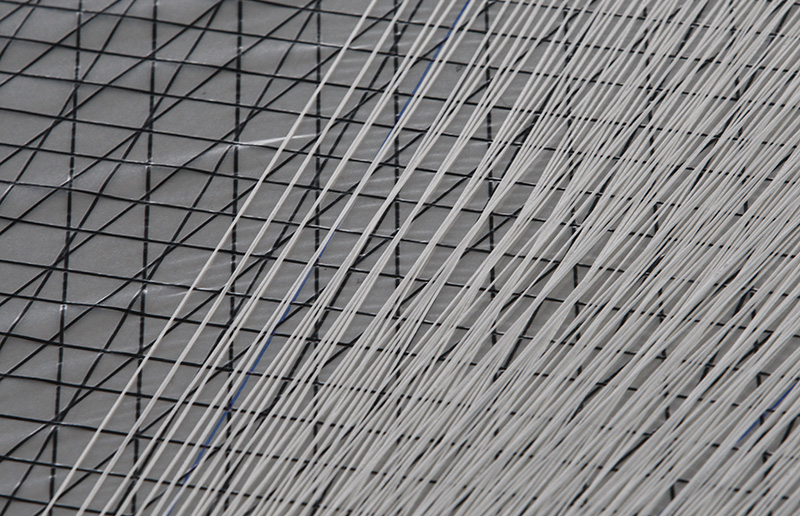

COMPOSITE CONSTRUCTION

The MACROS® membrane is a composite material and the ability of designer and manufacturers consists precisely in the careful choice and dosage of each single component needed: from the "external skin", which can be the Film, the Taffetta or the Soft Shell (a very light Non-Woven fabric based on micro-fibers obtained from thermoplastic polymers), the type and doses of glues and solvents that vary according to the type of fibers used, up to the melting temperature, the pressure and the vacuum holding time.

The goodness of the final product lies precisely in the correct dosage of this delicate balance.

In Olimpic Sails we have acquired these skills thanks to forty years of experience on regatta fields all over the world for boats of any type and size.

PERFORMANCE AND DURABILITY

The choice of the best type, or the optimal mix, of the fibers used according to the target of each sail, as well as the attention to the finishing details, guarantee high performances.

At the same time, MACROS® membranes are reliable and long lasting.

This mix allows us to satisfy the most demanding sailors as well as those owners who prefer the duration of a sail while not giving up high performances.

TAYLOR FIT

The art of the sailmaker consists in the "sartorial" skill with which each individual sail is custom-designed in order to fit perfectly according to the precise needs of each owner.